Any project involving fuel is going to require several things to happen beforehand in order to have a successful outcome. Therefore, proper management from the very beginning is essential when it comes to your next fuel project. For that, you must avoid these common mistakes people make when managing these types of projects.

Underestimating the complexity

Any project can appear to be simple in a PowerPoint presentation, but in reality, the situation can be a lot more complex. When you don’t see those complexities ahead of time, you may end up underestimating the schedule and budget and find yourself with a bunch of other issues as you go along. Although it’s always possible that the timetable and budget will have to change due to unforeseen complications, it’s best to know as much as possible about these potential issues before you begin any work.

One way you can avoid underestimating just how complex your fuel project might be is by partnering with an experienced fuel project service provider. Since the provider will have an experienced team reviewing your project proposal, they will be able to spot things you may have overlooked. This will allow you to make decisions ahead of time and more accurately plan your budget and schedule.

Lack of communication

Without clear, consistent and concise communication, a project can easily fail. As you search for a fuel service provider, be sure to consider the communication methods they use and how responsive they are to your questions and concerns from the beginning. If you are not getting timely and clear answers now, that is unlikely to change once your project is underway. When a provider cannot give you timely information about your project status and potential delays or problems, you will find yourself frustrated rather quickly. This can also negatively impact other areas of the project.

No petroleum project quality control

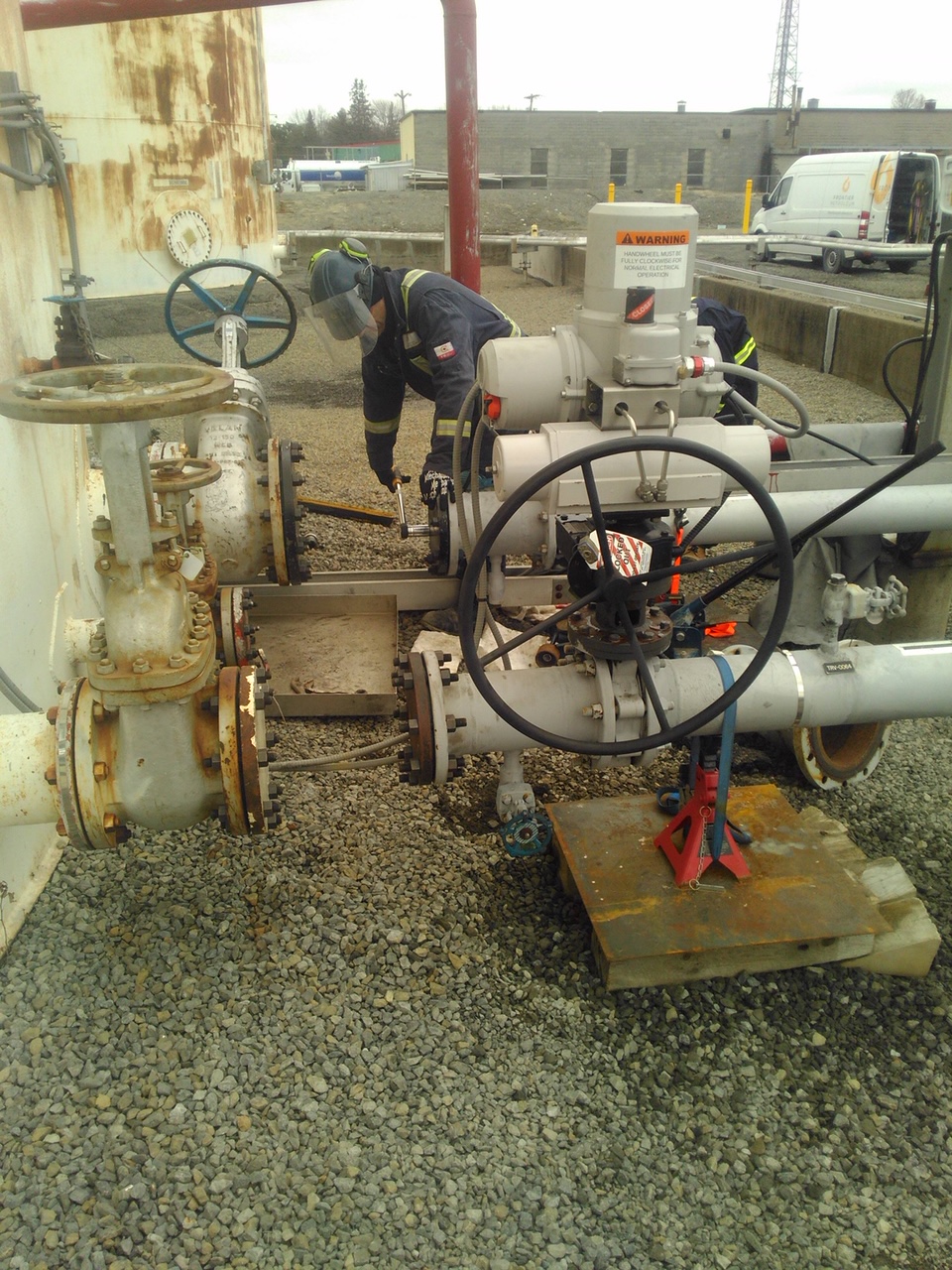

Quality control is absolutely necessary in a fuel project. Mistakes made in such a project can lead to environmental damage and even the injury or death of workers or other people on the project site. You must have a team of professionals dedicated to ensuring everything is done properly and in accordance with all applicable provincial and/or Canadian government regulations. Failing to have quality control in your project can lead to disastrous consequences for your business, including steep fines and other legal actions.

Using the wrong person for the job

You need to have people in place with the right skill set and experience for all the tasks involved in your fuel project. You may, for example, have someone who has welded before already present on your team, but that doesn’t automatically mean they are qualified to weld fuel pipes. Mistakes made by a person who doesn’t have the knowledge necessary to do the job properly can end up costing a lot more than if you had hired the right person in the first place.

Your fuel project outcome partly relies on how well you are able to manage your project from its inception. Contact an experienced petroleum service provider for help with your fuel project to position yourself for a successful outcome.